|

I. Summary

Easy 520 series is newly developed on the basis of national requirement and international standard ISO15883-1 on washing equipment for medical instruments in our company, with a technique of spraying manner of hot water to clean, disinfect medical instruments at 93℃ water temperature and also with oil coating, drying according to different features of objects by means of different processing programs, which can effectively protect operators and prevent cross contamination, meanwhile ensuring the cleaning result.

1. Improved efficiency:

With technical innovation Easy 520 efficiency is improved a lot compare with the old models, cycle time is only half of the traditional equipment of the same purpose and its capacity in one cycle is 15 DIN standard trays, 1.5 times of the old models.

2. Energy thrift:

By means of large runoff water circulation and spry system, 30% water is saved than the old model for the same amount objects being treated.

3. Easy operation:

Operation and program parameter settings can be done easily on the user friendly PLC touch screen.

4. Full cycle recording:

All function parameters and data through a cycle can be checked and recorded, put out by means of printer or computer.

5. Manufacture standard:

Easy 520 is newly developed on the basis of national requirement and international standard ISO 15883-1, suitable for washing disinfection and dry treatment to surgical instruments, utensils, narcosis apparatus, endoscope devices and etc in hospitals. With this the aseptic and non-aseptic rooms can be effectively separated to prevent recontamination. Core armoured glass doors are mounted at the front and back ends of the washer, through which inner operation can be viewed

6. With Eas520 all washing disinfection processes like washing (enzyme feed), rinse, disinfection (oil coating) and drying can be done consequently as a whole, one set can be used independently often but several joined together can be used for large quantity of washing work. Easy installation, operation and service are also considered during design for Easy 520.

7. Loading and unloading: Manual and auto loading and unloading can be optional by customer, available also are matching racks, trolleys and transportation system with ergonomics design concept.

8. Safe wash for Anaesthesia/respiratory tube: Rapid-520 can be used for treatment on anaesthesia instruments, respiratory tubes and all MIS instrument sets, simultenious washing can be carried on both inside and outside of anaesthesia tube.

9. Other racks for option:

There are bowl and kidney rack, multi-function rack, four level rack, micro-instrument rack, dental hand set rack, two level rack, glass and utensil rack as well as those special design according to customer requirement.

II. Type and nomination:

Rapid -□-□

Chamber capacity (L) Door operation manner (M manual, A automatic) Model name for washer disinfector Example: Easy 520 is an automatic door operation washer disinfector with chamber capacity 520 liters. Chamber capacity (L) Door operation manner (M manual, A automatic) Model name for washer disinfector Example: Easy 520 is an automatic door operation washer disinfector with chamber capacity 520 liters.

III. Structure and working principle

Working principle: Soften or distilled (pure) water as medium circulating inside the chamber pipes under the force of the large runoff pump spraying out from the jet to clean the objects to be washed, meanwhile a thorough clean can be achieved with automatic ringe-solution and coating oil, besides the cleaning water is heated automatically for disinfection on the objects

Easy 520 series consists of the chamber, frame, airproof door, pipeline system, rack, trolley, external covers, control system and etc.

1. The chamber:

A)Made of advanced threaded stainless steel and finely processed for washing;

B)Spot welding is adopted on the construction to minimize welding distortion;

C) There are installed two jetting arms, one on top and the other at the bottom of the chamber, which eject water to clean objects;

D)There is insulation material pasted on the outer surface of the chamber to reduce heat emission and noise.

2. The airproof door:

A)Automatic slide glass door (single or double and double door) is adopted, for the convenience of separating the aseptic area and the non-aseptic area;

B)When loading is done, touch the button on the screen to open the door and after loading touch the button on the screen to close the door;

C) The door is a two layer armoured glass structure, safe and heat-proof, also convenient for observation for the operation inside the chamber;

D) The door is moved up and down by means of gear driving on two sides with a stable performance, saving labor and protect the operator form contacting the contaminant.;

E) 3 safety measures:

1) Interlock device——The two doors are interlocked each other, the front door cannot be opened until the back one is closed, or vice versa. 2) Self locking——a cycle cannot be started until the door is closed and the door cannot be opened until the cycle comes to the end. 3) Safety lock—the airproof door will stop automatically when it meets barrier during its closure, this will not harm the operator and objects to be processed.

3. Pipeline system:

It consists of valves, water pump, wind blower, dosage pump, relative pipes and etc. for the procedures of water spray, heating, disinfection, oil coating hot air drying and etc. the system can be divided into water spray pipe, lotion entry and coating oil supply pipes, water tank heating system, hot air drying system and liquid level testing system. principle diagram.

A)The large runoff water pump makes water circulating through the spray jets to do efficient cleaning on the objects, the solenoid valve can does the function for water feed into the chamber and water discharge after washing;

B) The dosage pump supply lotion and coating oil into the washing water in the chamber automatically according to the designed proportion in the program for a better cleaning result and instruments surface protection after washing;

C) The heating system can heat the water inside the chamber according to the different requirements of various objects and various processes, Such as low temperature washing in the primary phase, 50℃ warm water rinse (lotion into the chamber at such temperature stage is the best), 93℃ hot water disinfection;

D) Hot air drying system consists of the large flow rate fan, valves, sterile filter and wind tubes, at the last stage of the cycle sterile hot air is supplied into the chamber for drying and after this the instruments can be packed for sterilization directly after the drying;

E) Water will be automatically discharged after a cycle before drying.

4. Control system:

The controller is a collection of control, display, touch for operation parameter setting, easy and convenient for viewing and processing.

A) Standard working procedures are: washing, first rinse, second rinse, third rinse (with disinfection), drying.;

B) On the touch screen operation stages and working parameters are dynamically displayed for easy viewing and manipulation;

C) There are 3 built-in programs and 27 reserved ones for customer’s choice on the equipment. E, The equipped printer for automatic temperature, time, graphic and A0 value printing.

5. External cover:

Made of threaded stainless steel sheet for decoration of the machine.

6. Rack:

A)Suitable racks can be chosen by the customer according to actual requirements for reasonable and efficient use with their objects to be treated;

B) Different racks for choice 4 layer rack, narcosis and breath tube rack, 5 layer instrument rack, glassware rack, bowl and tray rack, and others according to customers’ requirement;

C) On the 5 layer instrument rack there is a spray jet for each layer and 15 DIN standard trays can be loaded;

D) Narcosis and breath tube rack can be used for narcosis apparatus, and breath tubes, also inside and outside of the narcosis tube can be treated on this rack. E, Special racks can be optional for milk bottle, instrument holder, operation shoes and etc.

7. Trolley:

For carrying racks loaded with objects to be treated in and out of the washer chamber. Operation on the trolleys can be manual and automatic according to customer requirement.

IV. Working environment:

1. Temperature: 5-40℃, relative humidity:under 20℃ no more than 90%;

2. Place to be installed:

A. No strong magnetic field around;

B. Away from high temperature and high humidity;

C. Away from direct sunshine;

D. No fire source around;

E. Installed on a horizontal level basement;

F. Avoiding heavy dust, oil mist, corrosive gas and inflammable gas;

G. Good ventilation.

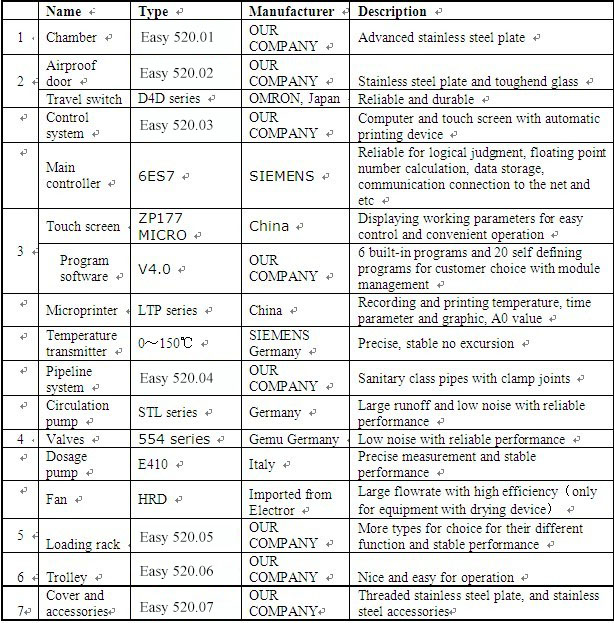

V. Easy 520 main component configuration:

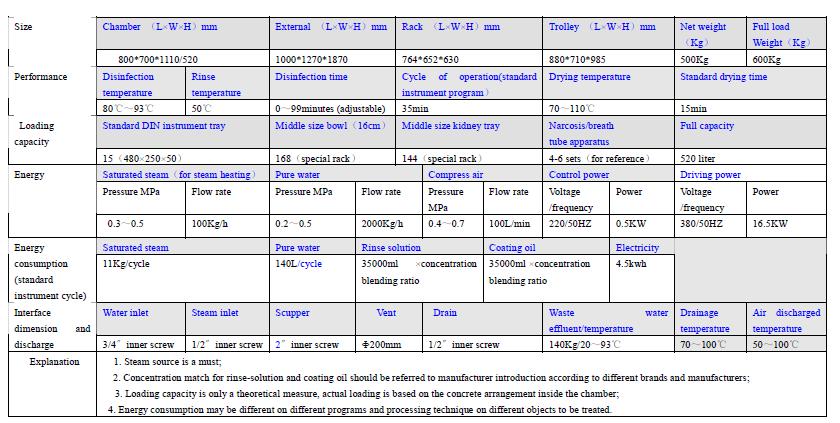

VI. Easy 520 technical parameters

|