|

185L Laboratory Glassware Washer

Application

Small size, easy to use, especially suitable for scientific research and education. It is an economical and practical cleaning machine for cleaning 96 100ml volumetric flasks or 300 2ml chromatographic sampling bottles at a time.

Product advantages

♦ Machine material

The shell material is 304 stainless steel and the cleaning chamber is 316L stainless steel, the cleaning chamber were formed directly without welding points, the pipe material is 316L stainless steel & pharmaceutical silicone. The volume of cleaning chamber is 185L

♦ Microcomputer chip control technology (non-PLC)

With 8.8 inch full color OLED LCD touch screen, including 30 standard procedures and 120 self-defined procedures.

♦ Variable frequency soft-start function

Adopt variable frequency soft-start functioncontrol the circulation pump from 0-400L/min. Pipeline pressure monitor monitors the pressure of the main pipeline in real time.

♦ New back water supply method with two parallel water supply

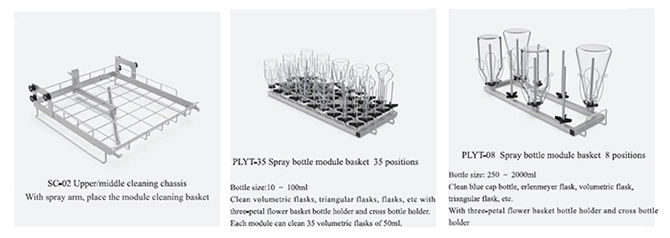

Basket adopts FL-EXCH module design, every 1/2 module can be exchanged freely. Up to 4 cleaning basket can be placed at a time, and can be flexibly combined to adapt to various vessels, volumetric flasks, auto-sampler bottles, headspace bottles, pipettes, test tubes, Erlenmeyer flasks, round-bottom flasks, reagent bottles, graduated cylinders, etc.

♦ Control system

Cleaning program and other data can display on screen in real-time.

♦ Drying system

YF-LW190 Remaining temperature drying

YF-LW190P Injection hot air drying, pipeline compression fan, air inlet is equipped with H12 grade HEPA filter, air volume 55m³/h, double condensation heat exchange system for steam condensation, temperature can be adjust-ed (room temperature -120°C), drying time (0-300min).

♦ Circulation system

Variable frequency soft-start function control the circulation pump from 0-400L/min. Pipeline pressure monitor monitors the pressure of the main pipeline in real time.

♦ Pipeline system

Cleaning basket identification technology

♦ New back water supply method with two parallel water supply

Basket adopts FL-EXCH module design, every 1/2 module can be exchanged freely.

♦ Safety protection system

• Electronic safety lock, EULA electric door opening and closing technology, the experimenter can set the door opening temperature limit.

• Water heating over temperature protection, hot air heating over temperature protection, water pump over temperature protection, fan over temperature protection.

• The instrument will recovery automatically after water cut and memory if the power cut off.

• The instrument have the remind function when the cleaning agent is lacking.

♦ Multi-layer filtration system

Prevent debris from entering the pipeline and causing blockage

| Parameters / Model |

YF-LW190 |

YF-LW190P |

| Power |

220V 5Kw |

220V 5Kw |

| Screen size |

8.8inch |

8.8inch |

| Standard program |

30 |

30 |

| Self-defined program |

120 |

120 |

| Pump flow |

0-500L/MIN |

0-500L/MIN |

| Printer interface |

- |

Yes |

| Drying system |

Temperature drying |

Injection hot air drying |

| Air heating power |

3Kw |

3Kw |

| Black box system |

Yes |

Yes |

| Cleaning basket layer |

two layers |

two layers |

| Intelligent switch door |

Yes |

Yes |

| 3 level permissions |

Yes |

Yes |

| Cleaning basket identification |

- |

- |

| Pipeline Pressure Monitoring |

Yes |

Yes |

| Fingerprint identification system |

- |

- |

| SD card store system |

- |

Yes |

| Cleaning chamber volume |

185L |

185L |

| External diameter (LxWxH) |

670x691x940mm |

670x691x940mm |

|