|

223L Laboratory Glassware Washer

Product advantages

♦ Microcomputer chip control technology (non-PLC)

The main control circuit adopts gold-plating technology and military-grade electronic devices.

♦ 7 inch full color OLED LCD touch screen operating system with fingerprint recognition system and SD card data storage system

The screen has automatic sleep and manual wake-up function, cleaning program can display on screen in real-time.

♦ 30 standard procedures and 120 self-defined procedures

Each procedure has codes and parameters without any combination, three-level password management system and online conductivity to monitor cleaning data and the value of AO.

♦ Double circulation pump adopts variable frequency soft-start function

The circulating water can be adjusted from 0-600L/min .The pipeline pressure was monitored through pipeline pressure detection sensors in real-time and the pump can be stopped when the pressure is too low or disappear.

♦ Back water supply method with two parallel water supply

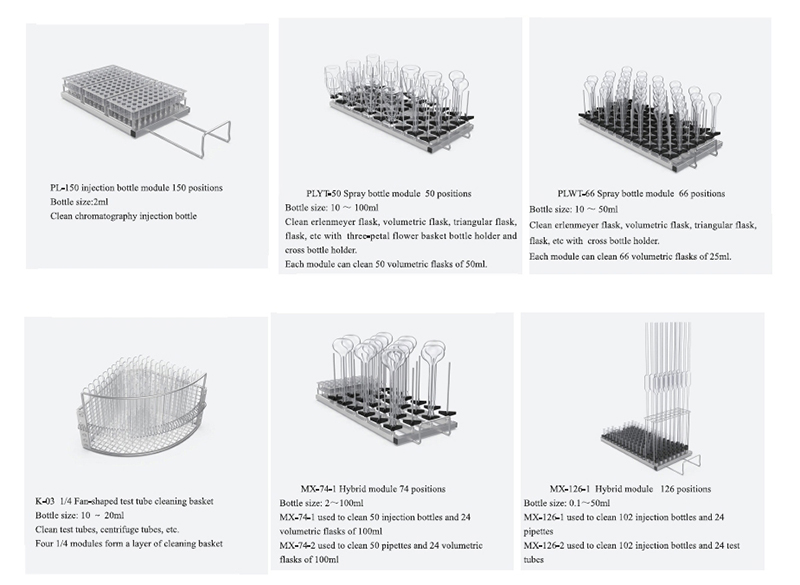

The pressure is uniform and the water outlet height is the same. Basket adopts FL -EXCH module design, every 1/2 module can be exchanged freely, basket frame and basket adopt quick-plug design, easy to install.

♦ Black box was set to record the running status

Buzzing and panel reminding after the cleaning, cleaning data can store and print.

♦ Instrument structure

The shell material is 304 stainless steel and the cleaning chamber is 316L stainless steel, the cleaning chamber were formed directly without welding points. The integrated design of the whole machine can be installed independently without the aid of other external devices, Four buckets of 5L cleaning agent can be stored inside and four universal casters at the bottom of the instrument for easy movement.

♦ Washing capacity

The cleaning chamber is 223L and double-layer cleaning basket can be placed.

Clean 40 reagent bottle of 1000ml or 72 volumetric flask of 250ml or 128 volumetric flask of 100ml or 600 chromatography injection bottle of 2ml or 120 pipette at the same time.

♦ Water circulation system

• Variable frequency soft-start function control the circulation pump from 0-600L/min.

• Dynamic water injection system: Flowmeter was set in to measure water and the panel displays water intake and process in real time to ensure the ratio of cleaning agent and water.

• Pipeline pressure monitor monitors the pressure of the main pipeline in real time. Double temperature monitoring system and optional drainage cooling and double drainage function.

♦ Data transmission system

6 or more user ports to enter with three-level password authority management. Fingerprint recognition authority management system and SD card storage audit trail system, the interface is RS232.

♦ Safety protection system

• Electronic safety lock

EULA electric door opening and closing technology, the experimenter can set the door opening temperature limit.

• Water heating over temperature protection, hot air heating over temperature protection, water pump over temperature protection, fan over temperature protection.

• Monitoring water leakage

The instrument will stop working if water leakage.

• The instrument will recovery automatically after water cut and memory if the power cut off.

• The instrument have the remind function when the cleaning agent is lacking.

♦ Multi-layer filtration systemPrevent debris from entering the pipeline and causing blockage.

♦ Drying system

HEPA drying system with double pipeline compression fan, the maximum vacuum pressure is 110 mbar and the circulation of hot air is not less than 110m³/h. Temperature from room temperature to 120íŠ and drying time from 0 to 300mins.

With double spray heat exchange system and EU-W water-saving condensing technology.

Technical parameters

| Parameters / Model |

YF-LW230 |

YF-LW230H |

| Power |

220V 50Hz |

380V 50Hz |

| Heating power |

4Kw |

9Kw |

| Pump power |

900W |

900W |

| Screen size |

7 inch |

7 inch |

| Standard program |

30 |

30 |

| Self-defined program |

120 |

120 |

| Pump flow |

0-600L/MIN |

0-600L/MIN |

| Printer interface |

Yes |

Yes |

| Drying system |

Injection drying |

Injection drying |

| Air heating power |

3Kw |

3Kw |

| Black box system |

Yes |

Yes |

| Cleaning basket layer |

2 layers |

2 layers |

| Intelligent switch door |

Yes |

Yes |

| 3 level permissions |

Yes |

Yes |

| Cleaning basket identification |

Yes |

Yes |

| Pipeline Pressure Monitoring |

Yes |

Yes |

| Fingerprint identification system |

Yes |

Yes |

| SD card store system |

Yes |

Yes |

| Cleaning chamber volume |

223L |

223L |

| External diameter (LxWxH) |

670x760x1400mm |

670x760x1400mm |

|