♦ Washing capacity

Large cleaning chamber with three-layer cleaning basket. Double-layer heat-resistant glass windows with built-in lighting. The three-layer cleaning basket can simultaneously clean 250ml volumetric flasks and 192 sets of 100ml of volumetric flasks or 120 sets of wide-mouth utensils, and clean 900 2ml chromatographic injection bottles at a time.

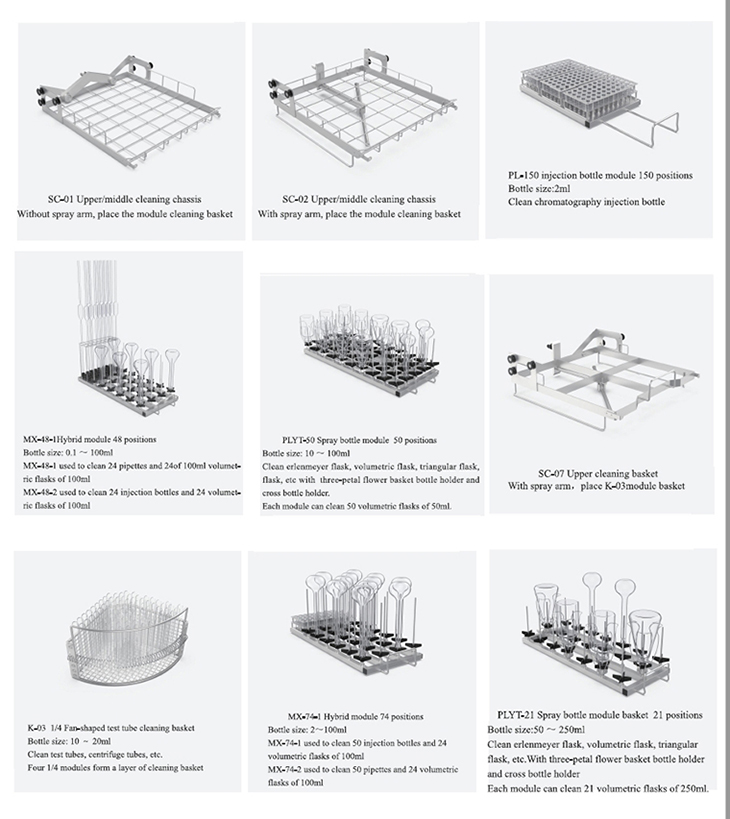

Convenient basket combination, it can put 6 modular baskets at a time. flexible combination to adapt to various utensils, volumetric flasks, automatic sample bottles, headspace bottles, pipettes, test tubes, Erlenmeyer flasks, round bottom flasks, Reagent bottles, measuring cylinders, etc.

♦ Instrument structure

The shell material is 304 stainless steel and the cleaning chamber is 316L stainless steel. The volume of cleaning chamber is 317L, and the cleaning chamber were formed directly without welding points.

♦ Control system

• Microcomputer chip control technology(non-PLC)with 7inch full color OLED LCD touch screen, fingerprint identification system, three-level authority management. All the data can display on screen in real-time.

• A variety of cleaning procedures were settled, including 30 standard procedures (such as fast cleaning grease, logical, lubricating oil, etc.) and 120 self-defined procedures, in each self-defined procedure. The user can adjust various cleaning parameters such as water source, cleaning temperature, cleaning agent type and addition amount, circulating water pump frequency and save them automatically.

♦ Circulation system

Variable frequency soft-start function control the circulation pump from 0-800L/min. Pipeline pressure monitor monitors the pressure of the main pipeline in real-time.

♦ Safety protection system

• Electronic safety lock, EULA electric door opening and closing technology, the experimenter can set the door opening temperature limit.

• Water heating over temperature protection, hot air heating overtemperature protection, water pump over temperature protection, fan over temperature protection.

• The instrument will recovery automatically after water cut and memory if the power cut of.

♦ Piping system

New back water supply method with two parallel water supply, Basket adopts FL-EXCH module design, every 1/2 module can be exchanged freely

♦ Drying system

High throughput pipeline compressor fan HEPA drying system, double spray heat exchange system, adopt EU-W water-saving condensation technology for steam condensation and cooling water automatic discharge.

♦ Data transmission system

6 or more user ports to enter with three-level password authority management. Fingerprint recognition authority management system and SD card storage audit trail system, the interface is RS232.

Technical parameters

| Parameters / Model |

YF-LW320 |

YF-LW320H |

| Power |

220V 50Hz |

380V 50Hz |

| Heating power |

5Kw |

10Kw |

| Pump power |

900W |

900W |

| Screen size |

7 inch |

7 inch |

| Standard program |

30 |

30 |

| Self-defined program |

120 |

120 |

| Circulating pump flow |

0-800L/MIN |

0-800L/MIN |

| Hot air circulation volume |

220m³/h |

220m³/h |

| Drying system |

HEPA drying system |

HEPA drying system |

| Air heating power |

4Kw |

4Kw |

| Drying temerature |

25-120°C |

25-120°C |

| Drying time |

0-300min |

0-300min |

| Black box system |

Yes |

Yes |

| Cleaning basket layer |

3 layers |

3 layers |

| Intelligent switch door |

Yes |

Yes |

| Cleaning basket identification |

Yes |

Yes |

| Pipe material |

316 stainless steel+pharmaceutical silicone |

316 stainless steel+pharmaceutical silicone |

| Pipeline Pressure |

110mbar |

110mbar |

| Pipeline Pressure Monitoring |

Yes |

Yes |

| Three-level authority |

Yes |

Yes |

| Fingerprint recognition |

Yes |

Yes |

| Printer interface |

Yes |

Yes |

| SD card store |

Yes |

Yes |

| Cleaning chamber volume |

317L |

317L |

| Chamber material |

316 stainless steel |

316 stainless steel |

| Shell material |

304 stainless steel |

304 stainless steel |

| Inner dimension (LxWxH) |

546x572x1016mm |

546x572x1016mm |

| External diameter (LxWxH) |

670x757x1650mm |

670x757x1650mm |